Creating a high-quality copy screen can be a challenge and is not as easy as most people may think. Simply having the right equipment and parts, such as LCDs (TM, AUO, IVO,etc.), glasses, frames, polarizers, backlights and so on, is not enough. It takes deep technical knowledge and experience. Let’s see how a copy screen is actually made.

As we mentioned before, companies like Tianma only produce LCD displays and do not assemble the screens. The LCD is important in the whole process, but not the most important element of the manufacturing. We’ll look at Tianma as an example here and also discuss company A, a LCD module factory, company B as agents, and company C as a laminating factory.

First, Tianma will study and produce an LCD display compatible with iPhones according to Company A's requirements. After receiving the LCD display, Company A will make a manufacturing scheme. Not every factory can do that. As far as we know, there are no more than 5 LCD module factories that have the ability to develop the scheme. According to the scheme, they will arrange production.

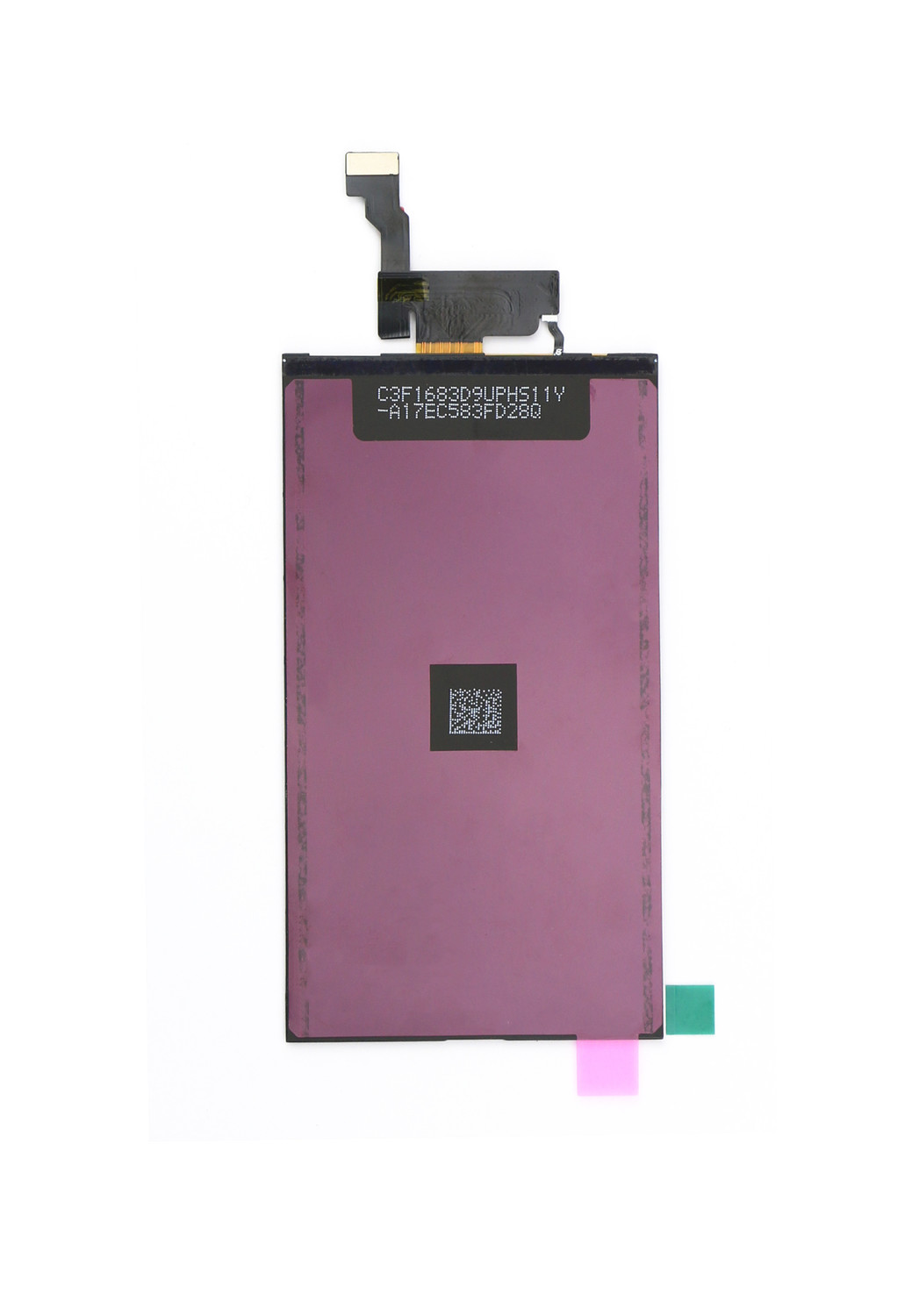

A factory then laminates the LCD with top and bottom polarizers with OCA, IC and an LCD Flex Cable (we call this a semi-manufactured FOG). You can see it below.

It seems to be a simple process, but only limited module factories can accomplish this. The technique needed to do it is extremely difficult to master.

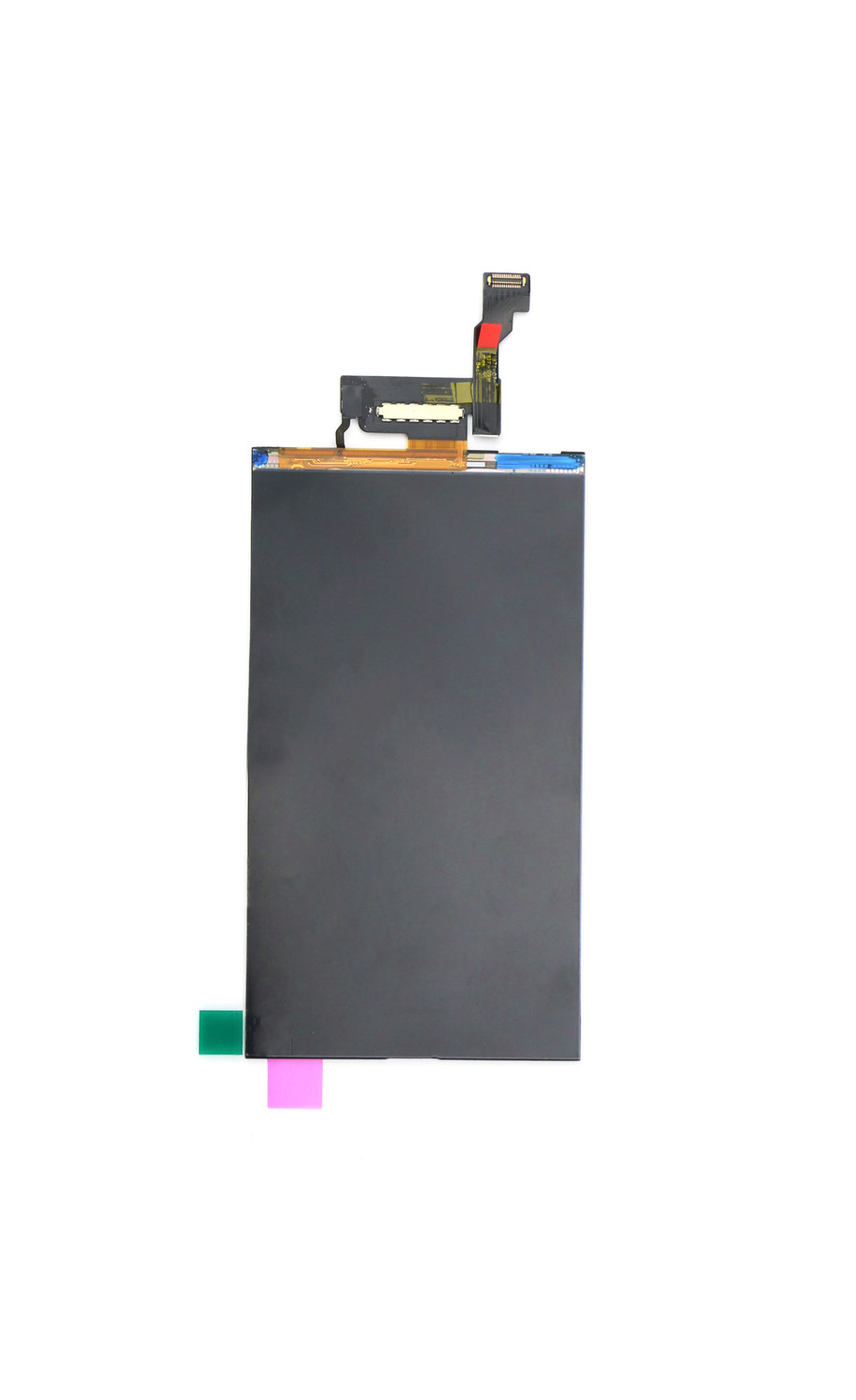

After that, Company A can sequentially laminate the FOG with backlights, which is called an LCD module. See the picture below.

Company A can sell FOG screens or LCD modules to its agents Company B, if it doesn't plan to assemble the screens. Then Company B will arrange the last lamination with Company C, the laminating factory. What does lamination entail? Company C, will laminate the LCD module with a touch panel followed with a bezel. This is how a screen is produced!